|

| October 12, 2021 | Volume 17 Issue 38 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Can superchargers help clean up two-stroke engines?

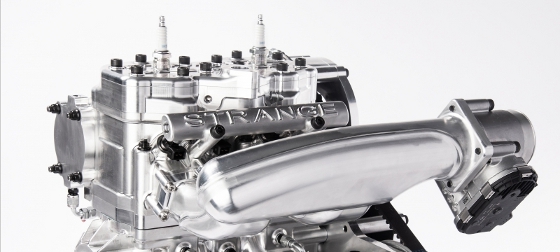

The REVolution engine uses a rotary exhaust valve (REV) to control emissions in a two-stroke engine, while a supercharger ensures power and performance. [Credit: Virginia Kamenitzer Ramsdell]

By Allison Mills, Michigan Technological University (Michigan Tech)

Mobility is changing -- it's electrifying. But not every vehicle is suited for electric propulsion and heavy battery systems. That's where the rotary exhaust valve (REV) is revolutionary.

The Advanced Power Systems Research Center (APS LABS) at Michigan Technological University is partnering with a company called Strange Development to test the REVolution engine, which uses a rotary exhaust valve to clean up what were previously some of the dirtiest engines on the market.

"Some sectors, especially drone sectors, don't have any emissions regulations. They're all two-stroke engines, and the problem is that regulation is going to catch up to them," said John Krzeminski, CEO of Strange Development. "Electrification is great for some applications, but it's not going to solve all our problems."

Specifically, Krzeminski and his APS LABS collaborator Jeremy Worm are looking at drones -- or rather, unmanned aerial vehicles (UAVs) -- and they are not your everyday hobbyist models. The researchers are also investigating range extenders for electric vehicles and utility powersports vehicles like the snowmobile an Inuit hunter might use, the all-terrain vehicle (ATV) a farmer relies on, or jet skis like the ones Michigan Tech engineers study at the Lake Superior marine autonomy research site.

VIDEO: A look at Strange Development's REVolution Engine.

The REVolution engine, a product innovation by Strange Development, and testing at APS LABS has been supported by a PlanetM Mobility Testing Grant through the Michigan Economic Development Corporation (MEDC). "Electrification is here. It's going to continue in the major transportation sectors, but that only makes us more susceptible to major power outages," Krzeminski said. "The truth behind the scenes: We need portable power generation. And right now we're using some dirty tech to provide that, but we want to fulfill that need in the most clean and responsible manner possible."

Rotary exhaust valves clean up dirty engines

The goal is creating a high-powered, lightweight, and clean two-stroke engine. Achieving that level of engineering elegance for internal combustion requires tailoring engine components to the job at hand. So, while the underlying tech could be adapted for many mobility applications, from UAVs to chainsaws to ATVs, the challenge lies in millimeter changes to fit the parts to the whole operation.

As Krzeminski explained in-depth alongside writer Rory Jackson for Unmanned System Technology, the REVolution engine uses a supercharger to keep high-pressure air directly in the engine's cylinder, and then the REV selectively closes or opens the exhaust port. Put simply, exhaust is waste -- the heat and emissions are lost energy -- so the supercharger gives a lot of oomph and the valve stops the engine from losing more than it has to. [Designfax Editor's Note: Please read this referenced article. It is full of more details.]

The REVolution engine's supercharger keeps high-pressure air directly in the engine's cylinder, and then the REV selectively closes or opens the exhaust port. [Credit: Virginia Kamenitzer Ramsdell]

Krzeminski stated in the article, "In 2015, Strange Development started running 1D simulations of a two-stroke with an axial-flow cylindrical rotary valve similar in principle to that developed by Bishop Innovation and Mercedes-Ilmor for the exhaust port in Formula One V10 engines. The company used the bottom half of its previous poppet-valve engine design but redesigned the top half to use a REV instead.

"The team quickly noticed that not only could the exhaust valve increase the two-stroke's power density, and yield more from supercharged induction, but depending on how the valve was timed, it could also enable better control of greenhouse gas emissions." ...

"If intake air escapes out through the exhaust, it's a waste of the supercharger, and reducing the oxygen content in the exhaust allows for add-on technologies such as catalytic converters that you don't usually get to use with a two-stroke," he said.

The overall goal is to meet higher emissions standards and keep the same performance as current two-strokes.

The first step toward that is creating a test bed.

APS LABS is known for bridging the gaps between internal combustion (IC) engines, alternative fuels, electric propulsion, autonomous vehicles, and connected technologies. Because automobile engineers are good at their jobs, many consumers aren't aware of the subtle evolutions and technology shifts under their car hoods. While some people may think it's a zero-sum choice between clean electric and dirty ICs, there is a lot more to consider in terms of environmental impact and practical use. What Worm finds most promising about the REVolution project is its blended approach to combustion and electrification.

"I hope there is a pendulum. I hope as a society, we see that there is not one size fits all, so we still need to develop combustion technologies," Worm said.

Using a grid-tied electric generator, APS LABS and Strange Development can test a new engine to generate power in the most clean and responsible manner possible. [Credit: MTU]

For now, the blended REVolution engine can't be tested on a regular dynamometer, or dyno, which measures an engine's force, torque, or power. Instead, the team had to use a motor from an electric vehicle as a sort of dyno to mimic the engine cycles a dyno would push a test engine through. The team working on the project includes staff research engineers Joel Duncan, Tucker Alsup, and Paul Dice from APS LABS.

The test setup takes the electric motor and its power electronics, then ties the setup to the power grid, enabling infinite supply or absorption of direct current (DC) power. That allows for repeatable and extended testing sessions. The setup enables not only testing and development of the engine technology, but also mimics a range extender, which helps electric vehicles go farther after they run out of juice.

Now that the test bed is ready and meets baseline standards, the next steps are to put the REVolution engine through its paces.

DESIGNFAX EDITOR'S NOTE: We have reached out to the researchers to provide some numbers on exhaust gas reduction values -- even if they are projected. We will update this article when we hear back.

Published October 2021

Rate this article

View our terms of use and privacy policy